Select an area to learn more:

Our sister company Fortis offers Mine Hoist Roping & Conveyance Services. Click here for more information.

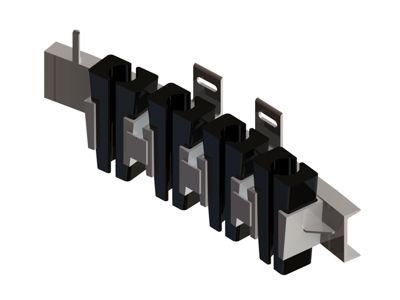

Becorit Drum & Sheave Liners

Northern Strands is an international supplier of Becorit liners. The Becorit hoist drum liners guarantee a very high friction coefficient, excellent abrasion resistance and a high permissible surface pressure. The Becorit liners can be made to suit any drum or sheave, and recommendations will be made for the right material for your specific job.

BECORIT: INNOVATION WITH A HISTORY

Becorit's success story began in 1926 with the production of frictional materials for conveying and lifting systems deployed in mining. Only 20 years later, Becorit GmbH develops brake pads for rail vehicles and becomes one of the most renowned producers of frictional materials worldwide. With the aid of technological innovation Becorit develops products of excellent quality you can depend on.

DIVERSITY AND FLEXIBILITY WITH SAFETY

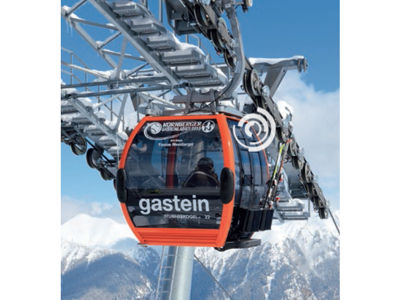

All over the world, Becorit's materials guarantee an optimal coefficient of friction between the wire rope and the sheave. Alongside the classical areas of application such as mining and funicular railways, you will find Becorit products in cable winches, fairground rides, steel rolling mills, crash test facilities and many other applications where traction and safety matter.

OUR LININGS KEEP WHAT WE PRO MISE

With strict adherence to the ISO 9001, ISO 14001 and ISO 50001standards, Becorit products are manufactured at our site in Recklinghausen, Germany. To guarantee the quality, all steps of the process, from raw materials to the finished part, are monitored and documented.

TRACTION SAFETY YOU CAN RELY ON

The efficiency and safety of the wire rope and the traction sheave is defined by the coefficient of friction between the wire rope and the lining. By taking this into consideration, Becorit selects the optimum lining material for the area of deployment. The following factors play a significant role as they have a direct influence on the coefficient of friction:

- Load condition

- Wire construction

- Acceleration

- Temperature

- Moisture

- Wire lubrication

- Contamination

Becorit Drum & Sheave Liners

Becorit Drum & Sheave Liners

Becorit Drum & Sheave Liners

Becorit Drum & Sheave Liners

Straightpoint Load Monitoring Products

Since 1976 Straightpoint’s world-class, solution-based systems have been at the forefront of industrial weighing and load monitoring technology. With UK headquarters, a US subsidiary, and global dealer network, the simple to use, cost-effective product range has enhanced safety for engineers and rigging professionals worldwide for 40 years. The engineering team design and manufacture a broad spectrum of first-class products to capacities in excess of 1,500 tonnes to include:

- Tension 'Link' load cells

- Telemetry load cells

- Shackle load cells

- Dynamometers

- Crane scales

- Compression load cells

- Load pins

- Software solutions

The Straightpoint team pride themselves on the development and distribution of world-class load monitoring, weighing and force measurement systems. Straightpoint’s wireless Windows-based software, and full line of accessories allow for the simple and easy, acquisition and analysis of force and load monitoring data. All Straightpoint products are fully tested and available for next day dispatch in an aluminium flight case (or wooden crate for large capacities) with full documentation including multi lingual manuals, certificates of calibration/proof test and CE conformity. World-class calibration and repair services are offered for all models as well as other manufacturers' load cells. Straightpoint products are utilised within many industries worldwide:

- Shipping and marine

- Mining

- Transport

- Health and safety

- Entertainment

- Crane and rigging

- Salvage and decommissioning

- Oil and gas

- Construction

- Power generation

- Utilities

- Topsides

- Break bulk

- Military

Straightpoint's highly qualified team of product specialists are available to assist with any application, and its global network of first-class distributors ensure that wherever your location, an approved Straightpoint dealer is close by. Straightpoint's continued investment in research and development enables them to remain at the forefront of technological development with world-leading products and performance to meet their customers’ demands. With hundreds of units always in stock, Straightpoint aim to deliver any standard product up to capacities in excess of 1,500 tonnes anywhere in the world—FAST!

Superior Warranty

All custom designed load pins and load cells are backed by our 2 year warranty.

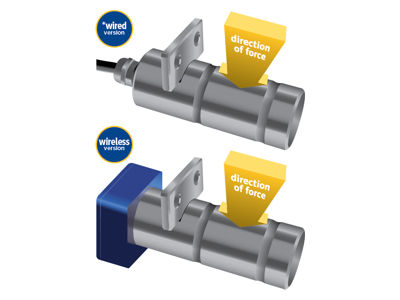

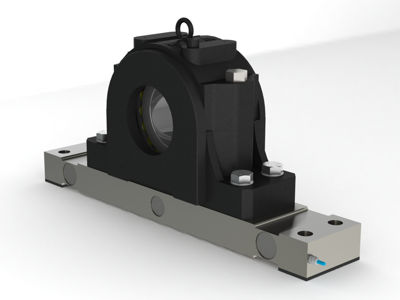

Pillow Block

Pillow Block type custom designed load cells for various mining applications. Can be used for mining and oil and gas applications.

Load Pins

Load pins, large and small are common for the Crane Service providers, mining and engineering companies.

Wireless Loadshackle

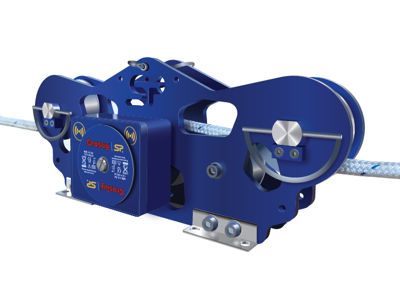

Running Line Dynamometer

Radio Link Plus

Miniweigher Plus

Loadpin

Loadlink Plus

Compression Load Cell

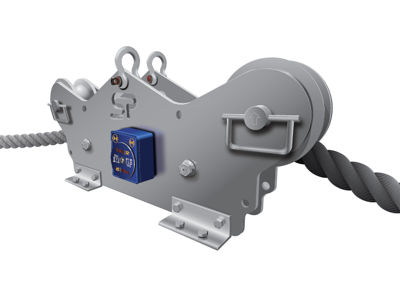

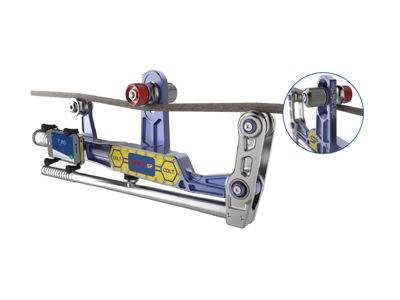

Clamp On Line Tensionmeter

Cable Safe

Blue Link Dynamometer

Through Hole Load Cells

Load Cells

Lubricants, Systems & Cleaners

At Northern Strands we know first-hand the importance of wire rope lubrication. It is required during manufacturing, installation, and ongoing maintenance. Different hoists and applications require different types of lubrication. We carry everything from basic asphalt lube to soap grease and no- petroleum based lubes. With Northern Strands’ knowledge of wire rope, we can recommend and supply appropriate lubrication products and suggest the best lubrication methods.

Type of products and equipment we supply lube and lube systems for includes:

- Tower Cranes

- Overhead Traveling Cranes

- Construction and Industrial Wire Rope

- Mining Surface Ropes

- Drum and Slope Hoist Ropes

- Progressioner Rope

Plus many more types of products and equipment. Contact us to inquire about the correct lubricant for your product or equipment.

Wire Rope Lubrication Systems

Northern Strands is a North American Distributor for CoreLube wire rope lubrication equipment and cleaners.

3100-BOS-R1 SYSTEM

The 3100-BOS-R1 System is designed to apply thick oils, semi fluids, and soft greases that are self penetrating.

Cable Size Range: 0.5" (12.7mm) to 3" (77mm).

Advantages:

- Ease of use

- Lubricates wire rope at speeds of 250 ft./min.

- One brush size fits a range of rope sizes, eliminating the need for a rubber seal for every size of rope.

- Wire rope deformities can be run through the unit.

- Wire ropes can run through the unit at any angle.

- The same pump fits all sizes containers from a drum to a pail.

A-1600-LB6 GREASE SYSTEM

The CoreLube A-1600 System is a high pressure wire rope grease injection unit for NLGI #00, #0, #1, and #2 grease.

Accommodates Wire Rope Sizes: 7/32" (5.5mm) to 2-9/16" (65.0mm).

Advantages:

- The Seals and Bushings snap into the housing without tools

- Solid machined housing with dual O-Ring seals

- Removes old lubricant, dirt, and grime

- High pressure 50:1 Pump

- High Output Volumbe Pump 4.25" (108.0mm) Air Motor

HELIX GROOVE CLEANERS

CoreLube Equipment's Helix Groove Cleaners are designed to remove contaminants from the valleys between the strands of wire rope. The cleaner works by rotating with the helical lay of the wire rope. The Helix Groove Cleaners are designed to work with CoreLubes applicator collars or thrust block.

Available Types:

- Diameter Ranges: 13.0 mm – 127.0 mm

- Number of Outer Strands: 3 - 18

- Left or Right Lay

- Round Stranded Wire Ropes

- Triangular or Swaged Stranded Wire Ropes

Wire Rope Lubricants and Cleaners

Northern Strands is an official supplier of Elaskon wire rope lubricants and cleaners.

Sheaves

Northern Strands offers many different sizes of Sheaves to suit various applications. This includes Head Sheaves, Defl ection Sheaves, Double Down Sheaves, And Custom Sheaves for Rope Installation and Removal. In House Engineering allows us to provide customers with the proper sheaves to suit their applications in regards to safe working load and factor of safety. Sheaves can be supplied with synthetic liners, or hardened grooves.

Sheaves

Sheaves

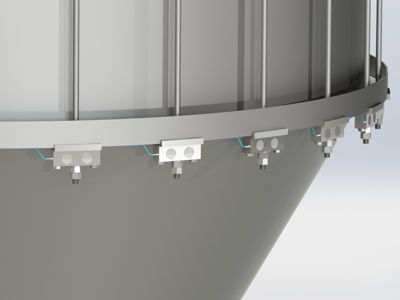

Electrical Cable Brackets & Installation

Northern Strands specializes in the design, fabrication and installation of electrical cable brackets and wedges.

Sheave Stand Assembly

Electrical Bracket & Wedges

Specialty Equipment

Installation & Reeving Equipment

- Deflection sheave assemblies with pedestals

- Double down sheaves

- Rope tensioners

- Reeving sockets

- Sheaves and pedestals

- D plates

- Maneuvering glands

- Suspension glands

- Safety blocks

- Safety clamps

- Gooseneck deflection sheaves

- Reel winder

- Wire rope shears (Hydraulic)

- Cappel banding press

- Socketing stands

- Snatch blocks

Maintenance Equipment

- Rope Lubrication Systems

- Rope Cleaners (Single & Multi Rope)

- Kellem Grips / Rope Grips

- Post-former

- Drum Liner Grooving Machines and Grooving Bits

Supplies

- Socketing resin

- Seizing wire

- Cleaners / degreasers

- Wire rope lubricants

Ropeman's Tools

- Grooving tools

- Seizing machine

- Socketing tools

- Sheave groove gauges

- Rope calipers

- PFV coated rope repair kit

- Punch lok tools

Mobile Reel Handler

Deflection Sheave Assembly with Pedestal

Reel Transporter/Unwinder

Maneuvering Gland

Reeving Socket

Wirelock Resin

Wire Rope Socketing Stand Rendering

Contact Info:

Saskatoon:

(306) 242-7073, Regina:

(306) 352-7073, Esterhazy:

(306) 745-4640 or email

sales@northernstrands.com for more information.