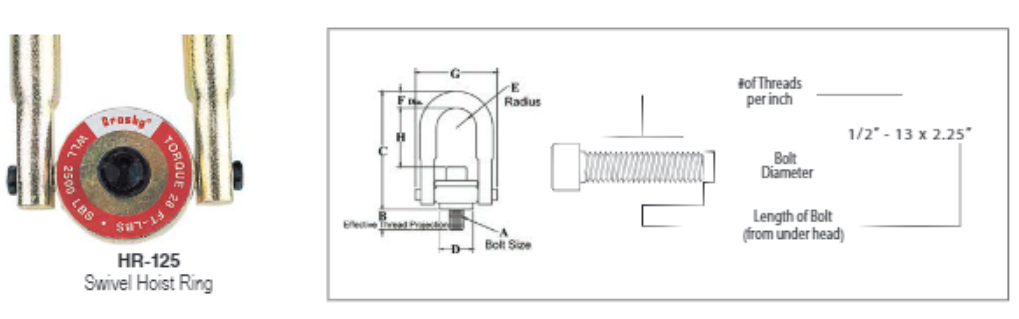

Northern Strands offers a numerous Crosby Rigging products to our customers. Crosby Swivel Hoist Rings have a variety of applications and are used similarly to shoulder eye bolts to help with connecting hooks and chains. Swivel Hoist Rings are rated at 100% at a 90° angle.

The Crosby UNC Swivel Hoist Rings are individually tested 2-2/5 times the recommended Working Load Limit. This ensures that the product will perform properly within the specified working load limit.

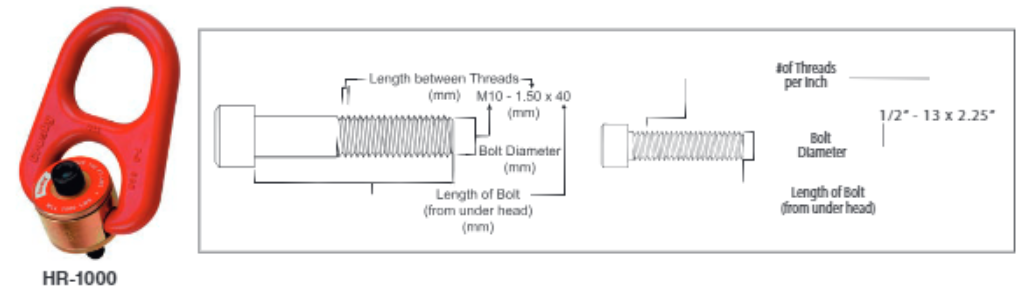

Northern Strands also supplies Crosby Metric Swivel Hoist Rings. This Swivel Hoist Ring washer is color coded for easy identification (silver & metric thread).

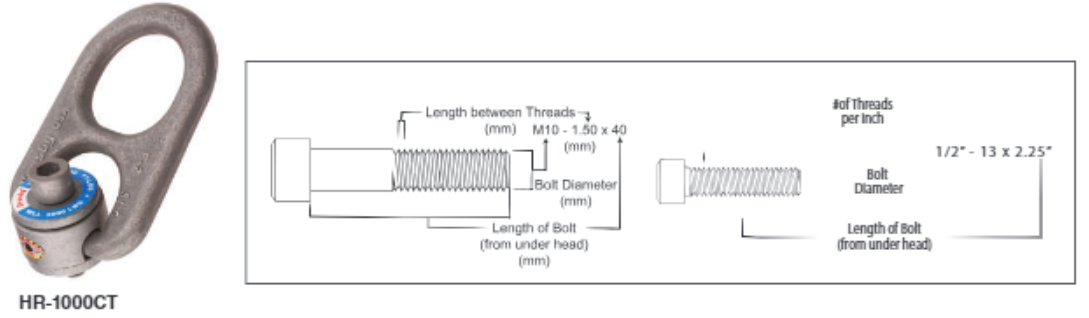

Crosby's Heavy Lift Swivel Hoist Rings have increased durability and can be used in less than ideal field conditions. The Heavy Lift Swivel Hoist Ring also has a larger opening than the standard Hoist Ring.

The Cold-Tuff UNC Heavy Lift Swivel Hoist Rings are produced with maximum hardness of 34 HRc. The body, brushing, washer, and bail have impact requirements of 31 ft-lbs minimum average at -4. The bolt has impact requirements of 20 ft-lbs with a minimum average at -150°F.

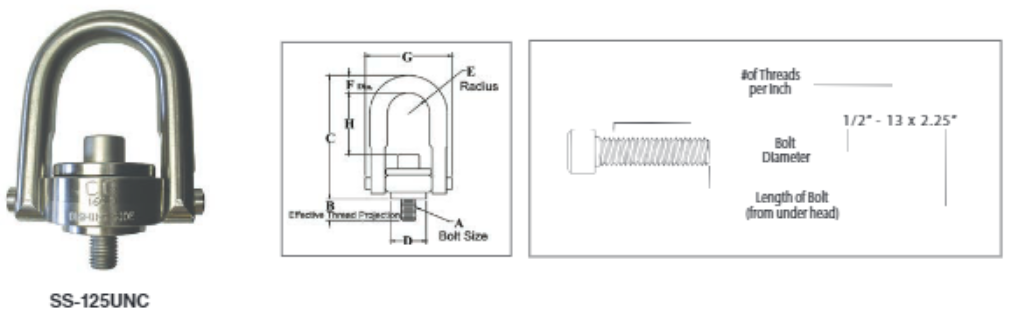

Stainless Steel Swivel Hoist Rings by Crosby are available at Northern Strands as well. All components are 316 stainless steel, execpt the bolt retainers that are made from 15-7 PH magnetic stainless steel. The Available capacities range from 400 lbs to 50,000 lbs. The Stainless Steel Swivel Hoist Ring is rated at 100% at a 90° angle.

It is important to use Swivel Hoists properly to ensure that work is completed safely. Never exceed the working load limit of a swivel hoist ring. Northern Stands offers a free sling calculator that can be used to calculate the necessary angles when using a swivel hoist and a sling. The Northern Strands Sling Calculator can be found here:

Sling Calculator

For additional information on Swivel Hoists or the other Crosby products offered at Northern Strands, please contact us!

Phone: 306-242-7073

Email: sales@northernstrands.com

Northern Strands, safety is one of our top priorities. Therefore, knowing how to properly clip wire rope using Crosby clips is very important in order to practice safe rigging. Keep in mind that the wire rope clip must be the correct size for the diameter of the rope that is being used and that there is a specific number of clips that are required according to rope size.

A quick rule of thumb for proper clip installation is, "Never Saddle a Dead Horse". This refers to the live end of the wire rope that rests in the saddle of the forged wire clip and the U-bolt that is placed on the dead end of the wire rope.

Here is the proper way to install Rope Clips as illustrated by the Crosby Group's 2015 General Catalog:

1. Turn back specified amount

of rope from thimble or loop. Apply first clip one base width from

dead end of rope. Apply U-Bolt over dead end of wire rope – live

end rests in saddle (Never saddle a dead horse!). Use torque

wrench to tighten nuts evenly, alternate from one nut to the other

until reaching the recommended torque.

2. When two clips are

required, apply the second

clip as near the loop or

thimble as possible. Use torque wrench to tighten nuts evenly,

alternating until reaching the recommended torque. When more

than two clips are required, apply the second clip as near the loop

or thimble as possible, turn nuts on second clip firmly, but do not

tighten.

3. When three or more clips are required, space additional clips

equally between first two

– take up rope slack – use

torque wrench to tighten nuts on each clip evenly, alternating from one nut to the other until

reaching recommended torque.

4. If a pulley (sheave) is

used in place of a thimble,

add one additional

Fist Grip. Fist Grip

spacing should be

as shown.

For more information on wire rope and wire rope clip installation, please contact us!

Northern Strands

306-242-7073

Email: info@northernstrands.com

Source: https://www.thecrosbygroup.com/catalog/