There are many worthwhile charities for companies to partner

with. Yet there are very few that offer a local and personnel connection like

Make-A-Wish Canada. The Make-A-Wish Foundation is a charity in Canada whose

grants wishes to critically ill children each year. The amazing work they do

changes the lives of these children and their families for the better! This

dedication to children and community aligns directly with the core values the

Northern Strands Group of Companies holds. We have committed to grant the wish

of one child each year for the past several years and everyone chips in to make

this a reality. Our teams take this commitment to heart, and we work throughout

the year make this donation possible each year.

With fundraising events not possible this year, our team

became creative in their fundraising efforts. Our staff rose to the challenge this

year and we collected recycling from all locations to send to SARCAN as well as

having a silent auction with donation items from companies we work with.

This last year we

sponsored a 7 year old girl named Alexis. She loves swimming, Lego and animals.

Her wish was to have a puppy! Through our donations and fundraising this year

we have been able to grant this wish for Alexis. She welcomed home a Cocker

Spaniel puppy this year.

The creativity of these kids and amazing strength and spirit

makes working with Make-A-Wish so much fun! There are quite a few children in

Canada waiting for a wish so check out their page at: https://makeawish.ca for ways you can get

involved or donate! It’s an amazing organization doing work to make the world a

softer and gentler place for critically ill children in Canada.

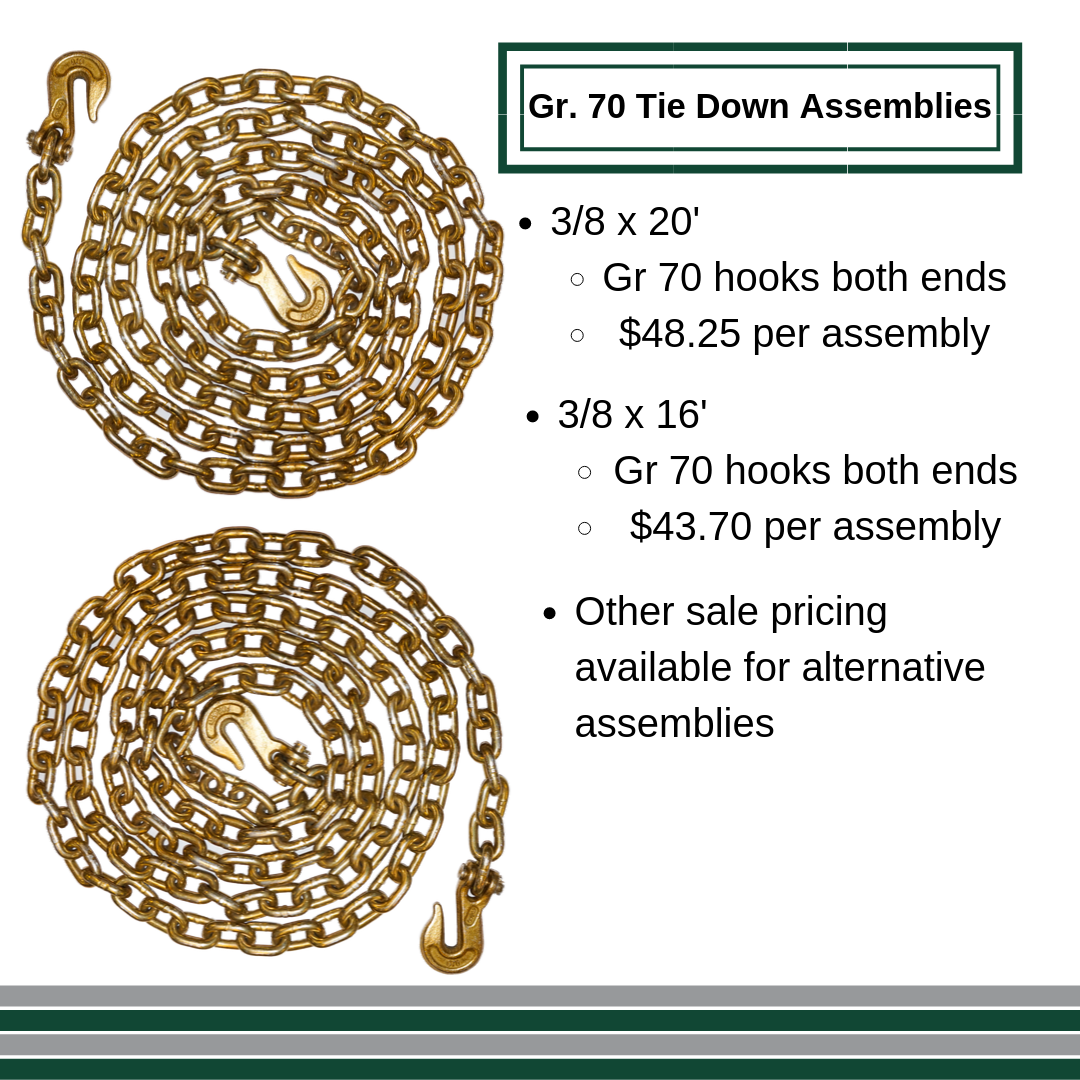

Just in time for fall, Northern Strands is offering a volume discount on a variety of load secure products!

Purchase 10 or more Lever Style Load Binders, Ratchet Style Load Binders, Gr 70 Tie Down Assemblies, and / or Ratchet Straps to receive a discounted per unit price!

Contact us today for more information about this sale!

Saskatoon: (306) 242-7073

Regina: (306) 352-7073

Email: sales@northernstrands.com

.png)

Northern Strand was honored to accept the Agriculture Equipment Innovation Award at Agri-Trade 2018 for our cutting edge Bin Safe System. The Agriculture Innovation Award is given to a company that celebrates new ideas, helps farmers meet new requirements, or provides a product to help meet new and changing needs in the agricultural sector. The judges for the Innovation Award are farmers; those who actually use agricultural products on their farm or ranch. The $1,500 price given to Northern Strands was donated to the Northern Strands Group of Companies' charity of choice, the Children's Wish Foundation of Saskatchewan.

The Bin Safe System is a farm safety equipment product that was developed to allow farmers to climb and easily access a grain bin for repairs or inspections. The system is an extremely cost effective alternative to grain bin walk ways, grain bin cages, and grain elevators. The implementation of new regulations in Alberta Farm Safety requires fall protection on various farms. Thus, the Bin Safe System helps farmers meet new legislative requirements and also provides the agricultural industry with a product to help meet new and changing needs on farms.

Up next for Northern Strands is the 2019 Crop Production Show hosted in Saskatoon Saskatchewan January 15 - 17, 2019 in booths C55-56. We will also be attending the Manitoba Ag Days Trade Show in the Inventor Area in Barn 4 Booth 1819 from January 22, 23, and 24th in Brandon Manitoba!

There are a number of important factors to consider when using chain to lift a given obstacle. Shiny, gold, Grade 70 Transport chain is intended for load binding only. This chain is used to hold heavy items down to a flatbed truck and the gold-chromate finish as well as the carbon-steel construction makes this chain easy to spot and more difficult to break.

With this said, this chain should not be used for lifting unless it has been fabricated by a sling manufacturer and the manufacturer is required to follow guidelines for fabrication. ASME and/or ASTM standards must be followed and they require that either grade 80 or 100 chain be used in sling fabrication, due to the alloy steel construction and its ability to elongate when overloaded as opposed to snapping suddenly. The manufacturer will also have to put a tag on the chain sling that indicates what maximum load or Working Load Limit can be safely applied to the sling, making it easier for end users to know the limitations.

When lifting any objects off of the ground, the weight of said object as well as the capacities of the lifting device and rigging must all be known before making the lift. This important guideline is something that the Northern Strands' Training Division focus on in the Below the Hook Rigging training. Sections 208 and 209 of the Saskatchewan’s Occupational Health and Safety Regulations refer to this concept directly as well.

When in doubt about whether to lift a load with a certain chain or not ask yourself this question: Does the chain have a tag on it indicating its Working Load Limit?

If yes – there are a number of other questions you should ask yourself after this to determine that all of the parameters related to the lift are safe.

If no – do not attempt the lift and look for an alternative solution.

When performing any sort of lift whatsoever, it is important that workers are trained in safe rigging practices and that they are competently supervised. Whether you are an employee or an employer, feel free to contact Northern Strands about our various Safety Courses and our Below the Hook Rigging Seminars.

For more information about Below the Hook Rigging Seminars click here: Hook Rigging Seminars

For more information about all Safety Training Courses click here: Safety Training Courses

Northern Strands Training Division Contact Information

Email: training@northernstrands.com

Phone: 306-242-7073

Did you know that a wire rope lanyard designed for fall arrest is not the same

as a wire rope sling that is designed for lifting?

When used as a fall arrest lanyard, wire rope by itself is unable to absorb any type of energy. Because there is no elasticity or stretch, this will subject a worker to a injury or even a potential amount of fatal arrest-force should they happen to fall while wearing it.

When wire rope is used as a connecting device, it is absolutely essential that a Personal Energy Absorber is used along with it. A PEA should actually be used with any lanyard or connecting device that allows for potential free fall, despite the fact that the webbing or rope of some lanyard types does actually absorb small amounts of energy.

Most jurisdictions, including Saskatchewan, prohibit fall

forces in excess of 8 kilonewtons. Therefore, employers are

legally required to ensure that a personal fall arrest system used by their

employees is set up in order to prevent arrest forces in excess of 1800 pounds.

The amount of force a human body can withstand has not

technically been verified by modern science. Less arrest force is generally easier on a person's body than more fall force. Additional information on this topic can be found here.

Wire rope slings should never be used as connecting devices in a Personal Fall Arrest System; it

will subject a falling worker to more fall force than a proper energy-absorbing lanyard would.

Northern Strands provides training on both the proper use of fall

arrest equipment and the proper use of rigging equipment. If you

would like more information one either of these programs, please contact us.

Contact us at:

training@northernstrands.com

306-242-7073