Over the years, as we have developed our AG Terminal Equipment Product line and expanded our inventoried items, it has become evident that the ability to obtain Pulley Lagging quickly or in an emergency in western Canada is difficult. Both Contractors and Companies have contacted Northern Strands multiple times to inquire if we carry Pulley Lagging? Trying to find stock from the established Belting supply companies has left them empty-handed, creating increased rush freight charges or expensive downtime.

Northern Strands is pleased to announce that we are stocking PPI's EZ-LAG and the required hardware for install. This can be used as a Bolt-in solution as well. If you have Bolt on requirements, any history of usage, etc. We have very competitive pricing and crews that can mobilize quickly for installation.

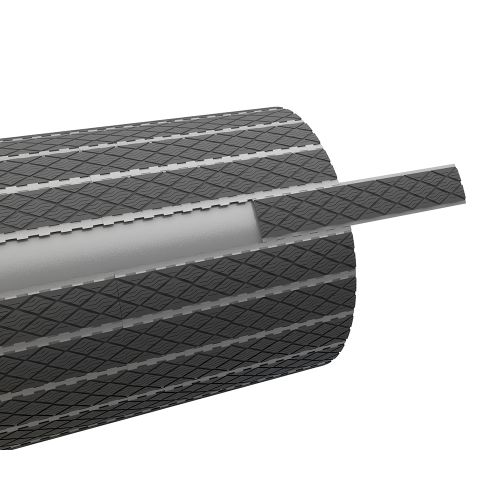

EZ-Lag Features and Benefits are many

- Traditional Sliding Lag has a solid steel back and needs to be ordered specific to the Pulley diameter, creating the need to stock multiple sizes at a high cost of inventory. EZ-Lag Has 2 strips of the metal backing plate, and is field formable from 12" diameters and up and recommend a Pulley face width of 36" down.

- On the spot re-lagging.

- Interchangeable with PPI Craft-Lag and Holz Lagging.

- Available in 60 durometers in SBR or Neoprene.

Northern Strands has recently sold and installed EZ-LAG in an Oil Crush Plant Pellet belt conveyor, Fertilizer Bucket elevator, and Grain handling Bucket elevator with great success. All customers were very satisfied with the install.

Contact us for a quote on EZ-LAG Pulley Lagging

Phone: 306-242-7073

Toll-Free: 1-800-242-7073

Email: sales@northernstrands.com

Northern Strands is locally owned and operated in Saskatchewan.

Northern Strands is excited to be a Dealer for Crosby Torque Driven Speedbinders in Saskatchewan and throughout Canada. What is a Torque Drive Load Binder you might ask? Torque Drive binders are designed and meant to be operated differently than any other load binder. It is best if your drivers can set aside any preconceived notions and past experience with operating binders. These require a new understanding of how they lock the chain tight. Done properly, drivers will experience less shoulder strain, easier operation, safer load securement, and faster tie-down/release times.

Let's start with the handle. Traditional load binders use a "paw" that is built into the handle to engage the gear around the barrel that, when rotated, pulls the threaded posts either in or out. This is not the case with the Crosby Speedbinder. The handle is not to be used in the traditional/rotational sense. The handle on the Torque Drive is actually a reaction bar first and handle for carrying second. Our load binder was designed to be operated by a cordless drill. In a pinch, someone can simply use a 14 mm wrench or socket if a drill breaks or batteries go dead.

The locking mechanism for Torque Drive is having the handle against the floor of the trailer or against a part of the equipment you are tying down. With the handle against (reacting) a stationary object, we develop superior chain tightness. Because we attain such high chain tightness, we virtually eliminate chains loosening with tire mash (bridge abutments, bumps, railroad tracks, etc.). Done correctly, it should take about five to seven pounds of force to pull the handle off the floor of the trailer.

Place the load binder as close to the rub rail as possible so that the handle will be able to hit the floor of the trailer or position so the handle is against a part of the unit being tied down.

We recommend the use of the Dewalt DCK299P2 drill kit (1/4” impact as backup) or a similar type drill. We use this drill for several reasons:

- It has superior torque than an impact.

- It has speed and torque. Run in either third or second for slack pick up, drop her into first or final tightness.

- The (2) five-amp-per-hour batteries should give a driver two to three full days of operation.

- The many torque settings allow the driver to set the chain tightness to his liking.

How to operate:

- Attach the handle to your drill to help curb the rotational forces that you will be applying. It is important to use both hands.

- We recommend setting the torque setting (dial on the collar) to seven to start. This gets most chains super tight. Adjust up or down the numerical range to best suit your needs.

- Run your slack in on second or third gear (look for the switch on top of the drill) and reduce down to first gear when you feel any hint of the drill pulling down.

- As your chain appears to be getting close to the desired tightness, ease on the trigger because you will begin to experience some twisting torque on the drill. This thing is powerful...again, it is important to use both hands.

- We have approved the use of a 3/8 impact. It is lighter, more manageable, and you can operate with one hand. Please do not use a 1/2 impact. This will void the warranty. The trade-off is that the drill gets the chains tighter, but you will have some twist to counter. The impact is easier to use and will wear the drive bolt a tad quicker. Drive bolts take about five minutes to replace.

Speedbinder Testimonial

"Finally pulled the plug and got my Speedbinders! The very next day, I received a load that required eight chains (before this I used to purposely pass up on loads that needed chaining because I didn’t want to deal with the chains). I started on the first chain and before I even got it tight I was kicking myself for not getting these a year earlier. The trucker next to me waiting to get loaded came around his truck when he heard my drill and was very impressed with the ease of use and how tight the chains were. I have since driven that load more than 700 miles, and I have not had to tighten a single binder down — NOT A SINGLE BINDER WAS LOOSE THE ENTIRE TRIP.

I am completely sold on these binders and will be getting four more to make sure I have enough for all the future loads I will be pulling using my chains and Speedbinders!

Thank you for making a great product!"

– Brian@2btrucking.us

Here's a great Torque Drive Load Binder demonstration video!

Email: sales@northernstrands.com

Phone: Saskatoon 306-242-7073, Regina 306-242-7073 or Esterhazy at 306-745-4640

One of Northern Strands first industrial equipment suppliers was Caldwell Lifting Solutions. The Caldwell name is well known throughout the Mining and Construction industries as one of the most reliable suppliers of material handling products. The Caldwell company has been supplying industry since 1954.

Some of Northern Strands most requested Caldwell products include:

- Adjustable spreader beams / lifting beams

- Adjustable forks pallet lifter

- Sheet lifters - Motorized, manual or battery operated are all popular

- Beam clamps

- Beam Trolleys

Contact Northern Strands for a quote on your next Caldwell product.

Email: sales@northernstrands.com

Phone: Saskatoon 306-242-7073, Regina 306-242-7073 or Esterhazy at 306-745-4640

Did you know Northern Strands is the largest supplier of wire rope and rigging in Saskatchewan? Our buying power means you get the best price on all types of wire rope and rigging, including farm equipment implement cables, tow / belly cables, harrow cables, fencing wire, and all types of wire rope a farm would need. Northern Strands also carries a variety of synthetic ropes, including double braid tow ropes, Dyneema winch lines, soft shackles, and more.

Northern Strands fabricates tow and harrow cable assemblies for tractors for approximately 40% less than the dealer or equipment manufacture! Belly or tow cable refers to the wire rope that connects under the tractor from the front of the tractor to the back drawbar. Harrow cables are used on the harrow wing booms. The harrow cables keep the wing booms in line with the rest of the harrow. Harrow cables are typically fabricated from 6x19 galvanized aircraft cables. Where belly cables are made from 6x19 bright steel.

For Northern Strands to provide a belly or harrow cable repair quote we will need the following:

- Diameter of wire rope

- Pull point to pull point measurement (as shown in the image below)

- Cable type - Harrow Cable or Tow Cable

- Eye type - Standard or Thimble Eye (drawing below shows thimble eye)

Contact us today:

Phone: 1-800-242-7073

Email: sales@northernstrands.com

Or visit one of our Saskatoon, Regina, or Esterhazy locations

https://www.northernstrands.com/contact-us.aspx

It's not every day a truck falls through ice and the solution to lifting the truck out is adding more ice, but that was what Big Ice Services had to do to lift a truck out of Slave River near Fort Chipewyan. The truck was stuck in very thin ice on the fast-moving Slave River. To safely remove the truck, Big Ice Services had to spend almost a month thickening the ice with their state-of-the-art ice-making equipment. Once the ice was thick enough they had to set up a lifting apparatus around the truck. Big Ice Services contacted Northern Strands to procure the rigging equipment needed for the job. A variety of rigging equipment was needed, including Aircraft Cable, Bright Steel Cable, Wire Rope Slings, Shackles, Sockets, Web Slings, Fall Protection Equipment, and other Rigging Accessories. It took Big Ice Services about five hours to successfully cut the truck out of the ice and then additional time to rig the truck (with ice attached) lifting it out of the ice. In total, the truck and ice weighed in excess of 30,000lbs. Great job Big Ice Services!

This particular job has gone viral online and CBC interviewed the owner of Big Ice Services, Ray Rossington, for the story. You can watch it here https://twitter.com/CBCTheNational/status/1376474218989191173

Big Ice Services is a very diverse company and we suggest visiting their website to learn more about their capabilities and services http://bigiceservices.ca/

Contact Northern Strands next time your company requires rigging, industrial supplies, or equipment.

We are proudly Saskatchewan owned and operated